全电脑无缝内衣机

Fully Computerized Seamless Underwear Knitting Machine

为了更方便、快捷的为客户提供进出口贸易业务,公司于2023年特成立了苏州赐画科技有限公司,专业为客户提供优质纺织机械、配件、原材料等相关产品,现已与国内外多家知名企业建立了长期友好的合作伙伴关系。

In order to more conveniently and quickly for providing customers with import and export trade business , We established Suzhou Cihua Technology Co., Ltd in 2023.Specializing in providing customers with high quality textile machinery, accessories, raw materials and other related products. Now, the company has established long-term and friendly cooperative partnership with a number of well-known enterprises at home and abroad.

1. COMPANY INTRODUCE

The manufacturer was found in 2003 in China,which is high-tech enterprise, the ministry of science and technology ‘torch plan’ project independ research and development company, one of the China’s first Intelligent knitting underwear machine national industry standard of drafting member. The company is located in Hangzhou economic and technological development zone near by the famous Qiangtang River. The transportation and conditions are convenient and unique.

Golden specialized is engaged in the intelligent knitting underwear machine manufacturing and knitting intelligent control system research and development, the company registered capital of 80 million RMB, a total investment of 200 million RMB, is engaged in the development and manufacture of technical team of more than 100 people. The company also have many high-tech laboratory, including electrical research and development laboratory, machinery research and development laboratory, Pattern research laboratory. The company also have an extensive and further research cooperation with Zhejiang sci-tech University.

The company’s major products are intelligent knitting underwear machine,GD-NJ08,GD-NJ12,GD-SNJ08,GD-SNJ12 etc, with stable performance and simple operation, similarly with same international products; Through the accumulation of technological innovation, the company’s independent research and development of intelligent control system, has formed his own core technology advantages, becoming the most excellent domestic knitting equipment control system. The company with excellent product quality, advanced technology content and the high quality post-sale service, has own the general customer favor, The products sell well in the domestic market and export to overseas.

In future, the company will be depending on the quality, technology and development of life’s business philosophy, and the same time, according to the market orientation, create more perfect top-class products.

2. MACHINE INTRODUCES

GD-NJ08 full computerized seamless underwear knitting machine have been studied by our company for several years, with experience & technique in producing the model GD-SNJ08 and GD-SNJ12, it was been innovating and upgrading and it can automatic knit the rib stitch according to technology without other auxiliary equipment, the machine can knit terry and it ctuck stitch besides the great function of fleecy and jacquard, it can produce various garment fabric mainly including under-wear, out-wear, swim-wear, sport-wear and health fabric.

3. MACHINE TECHNICAL PARAMETERS

Feeds | 8 Feeds |

Kinds of needles | GROZ |

Control program | IC researched by ourselves controls all of the output , and receive program and data by USB |

Broke yarn sensor | Totally 43 photoelectric yarn sensor |

Driving system | The servomotor is driven by timing belt wheels |

Compressed air | Under 6 Mpa , 50L /minute |

Absorbed air | 10 M3 |

Power | 2.2Kw |

Maximum speed | 80-125 RMP |

Needle selector | 16 level ,WAC |

Loop-forming device | Adopt stepper motor to control ,and adjust the stitch density fast , Density code tray is adopted cam resear ched by ourselves, have the leading domestic level |

Take down | 2 blower or central blower equipment |

Yarn feeders | 1 yarn feeders per feed, and there is a elastic yarn feeders for 2 and 6 |

Screen | COLOR LCD |

Pressure | -0.8 Mpa |

Size | 1900*1100*2100 mm (L*W*H) |

Weight | 700Kg |

4. MACHINE SPECIFICATION

Gauge: 28G(Special gauge also can make) | ||||

Diameter | Needle | Diameter | Needle | |

12'' | 960N(ABOUT 11'') | 17'' | 1536N | |

12'' | 1056N | 18'' | 1632N | |

13'' | 1152N | 19'' | 1728N | |

14'' | 1248N | 20'' | 1824N | |

15'' | 1344N | 21'' | 1920N | |

16'' | 1440N | 22'' | 2016N | |

5. MACHINE PRODUCTION(24 Hours, Speed 80RPM)(PCS)

Material/Product | Clothes Suit | Under BRA | Boxer |

Cotton | 120 | 500 | 600 |

Nylon & Polyester fiber | 130 | 450 | 700 |

Remark: This machine can make all the kind of underwear products, and above is the main products, the quantity is not very accurate.

The production is related to the product’s weave, jacquard or not, the product’s length and weigh….

6. Models

GD-NJ08 (With China Brand Needle Selector) | Diameter |

12''-15'' | |

16'' | |

17'' | |

18'' | |

19'' | |

20'' | |

21'' | |

22'' |

GD-NJ08 (With JAPAN WAC Needle Selector) | Diameter |

12''-15'' | |

16'' | |

17'' | |

18'' | |

19'' | |

20'' | |

21'' | |

22'' |

GD-SJ18 (FAST Machine) | Diameter |

12''-15'' | |

16'' | |

17'' | |

18'' | |

19'' | |

20'' | |

21'' | |

22” |

7. FREE SPARE PARTS

One tool box for 2 machines(including: U disk,Needles,Instructions,Screw,Spring,Leather collar and etc.)

8. MACHINE INSTALLATION

When the machine arrived customer’s factory, the customer should inform us, then we will send our engineer to the their factory, during the installation time, the customer should bare our engineer’s full room and board charges.

9. MACHINE WARRANTY

The machine warranty is 12 months(except the easily broken parts, example needles, belt, Sinker needle, Jacquard needle, half needle and etc.),for the non-consumable parts, should use the replacement parts for new parts. If the machine broken, we will send the engineer to repair it, but the engineer’s plane ticket, living, eating will responility by customers.

10. SHIPMENT AND DELIVERY TIME

About 90 days after received the deposit .

11. PAYMENT

30% contract value in advance as deposit, and the balance will be paid before the delivery.

12. TRAINING

Free training for 2-3 peoples about the machine operation.

13. THE QUOTATION VALIDITY TIME IS 15 DAYS.

14. One Container(20Ft) Load 6 Sets Machine, One Container(40Ft) Load 12 Sets Machine.

20FT的小柜装载6台,40FT的柜能装12台机器。

15. SUPPLEMENTARY MACHINE/机器运行所需附属设备:

Each group (6 Set machines) Equipped with the following machine: 每组机器(6台)需要标配以下设备: | ||

Machine/机型 | Power/功率 | Price/单价(以下设备品牌较多,不同品牌间价格相差较大,故单价为区间价格) |

Air Compressor空压机 | 5.5 kw | USD 1600.00-2400.00 |

Blower吸风机 | 5.5 kw | USD 1000.00-1900.00 |

Air Tank储气罐 | 1.0 M3 x 2 | USD 200.00-500.00/pc |

Dryer冷干机 | 1.0 M3 | USD 200.00-625.00 |

Regulator稳压器 | 30KVA | USD 700.00-1400.00 |

16 . Sewing Machine/缝制设备

3 Sets Machine For Bra,The Quantity is about 1500 Pcs/24H, 3 Sets Machine For Boxer,The Quantity is about 1500 Pcs/24H,So Need About:2 Sets 4 Needle 6 Thread Machine,1 Set Bartacking Machine,2 Sets Overlock machine and 1 Set Thread Cutting Machine. 以3台机做文胸和3台机做平角裤为例,文胸按每台机每天产量500件计算,3台机每天产量为1500件,平角裤按每台机每天产量500件计算,3台机每天产量为1500件,故大约需要(由于国外工人不熟练,工人产量会低于国内):2台4针6线,1台套结机,2台包边机,1台剪线头机。 | |||

Machine/机型 | Price(Different Brand,Different Price) | Sets | Remark |

4 Needle 6 Thread Machine/4针6线 | USD 2800.00-3900.00 | 2 | 700-1200 Pcs/12 H/1 worker |

Bartacking Machine(Interlock Machine)/套结机 | USD 2300.00-6200.00 | 1 | 20000 Pcs/12 H |

Stitch Machine/工业缝纫机 | USD 500.00-1300.00 | 700-1200 Pcs/12 H/1 worker | |

Thread Cutting Machine/剪线头机 | USD 600.00 | 1 | 20000 Pcs/12 H |

Overlock Machine/包边机 | USD 650.00-1700.00 | 2 | 700-1200 Pcs/12 H/1 worker |

Electric Scissor/电剪刀 | USD30.00-50.00 | 3-4 | |

IRON TABLE/整烫台 | USD 950.00-1600.00 | 1 Set With 3 pcs Iron | 1000-1500/Pcs/12H/1 worker |

17. Other Relation Machine 其他染色所需机器

Machine | Price | Model | Work Time |

Wash Machine/水洗机 | USD 3400.00-4700.00 | 100Kg-1 Set | 30-40Minutes/Time |

Dehydration Machine/脱水机 | USD 2500.00-3850.00 | 130Kg-1 Set | 10 Minutes/Time |

Dry Machine/烘干机 | USD 2500.00-3600.00 | 100Kg-1 Set | 40 Minutes/Time |

Dyeing Machine/染色机 | USD 7100.00-9000.00 | 100Kg- 1 Set | Cotton & Nylon 3-4 Hours/Time |

Seamless Machine-Half Product-Cutting- Sewing Stitch-Wash or Dye-Forming- Packing

NO./序号 | PROCESS/流程 | MACHINE/所需设备 | REMARK 备注 | |

1 | SEAMLESS MACHINE/机器上线(原料) | RAW MATERIAL | ||

2 | HALF PRODUCT/下机(半成品) | |||

3 | CUTTING/裁剪 | SCISSOR OR ELECTRIC SCOSSOR | ||

4 | SEWING STITCH/后道缝制 | a.Stitch/拼裆 | 4 Needle 6 Tread Machine/4针6线缝纫机 | For Boxer/平角裤缝制流程 |

b.Interlock/打套结 | Interlock Machine/套结机 | |||

c.Cutting Thread/剪线头 | Thread Cutting Machine/剪线头机 | |||

a.Overlock/包边 | Overlock Machine/包边机 | For Bra/文胸工艺流程 | ||

b.Interlock/打套结 | Interlock Machine/套结机 | |||

c.Cutting Thread/剪线头 | Thread Cutting Machine/剪线头机 | |||

5 | DYE/染色 | Dyeing Machine/染色机 | ||

6 | WASH/水洗 | Washing Machine/水洗机 | ||

7 | DEHYDRATION/脱水 | Dehydration Machine/脱水机 | ||

8 | DRY/烘干 | Dry Machine/烘干机 | ||

9 | FORMING/整烫定型 | IRON TABLE/整烫台 | ||

10 | PACKING/包装 | |||

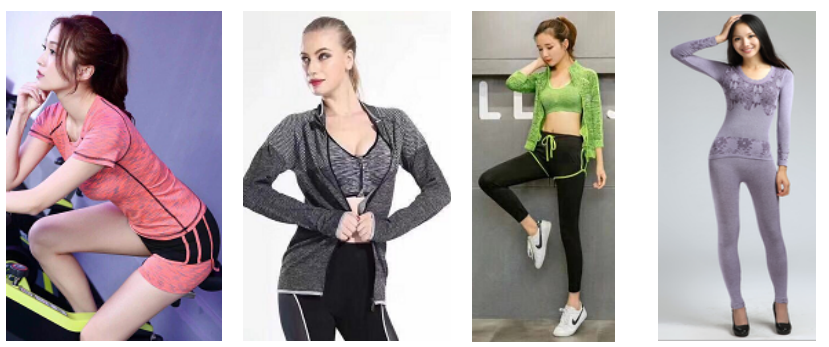

19.PRODUCT PHOTO

DIAMETER:12''- 22''

PRODUCTS:

Lady:Clothesuit/Underwear/Boxer brief/ Headcoil/lady thick underwear and etc.

Man: Clothes suit/Boxer brief/ man thick underwear and etc.

Health fabric-Sport-wear-Fat Clothes-Swim-wear......

According to China market:

12''-14'' product most for Children & Lady & Head coil and etc.

14''-17'' product most for Man & Lady thick underwear and etc.

18''-22'' product most for Sport-wear, Fatter Clothes and etc.

QR CODE

QR CODE