Safety Precautions

Supply and environmental conditions

1.Our machine only use the type of power source indicated on the product nameplate. More than 10% of the power fluctuations, must be equipped with power regulator

2. Power line should be fixed and taken security measures according to the provisions, can not bear any force

3.Device must be connected to ground, bad ground will cause electric shock and impact of safe and reliable operation of the product

4.The control system should be worked in clean, ventilated environments. Do not pile debris around the control box so as to facilitate cooling, and dust should be cleaned regularly

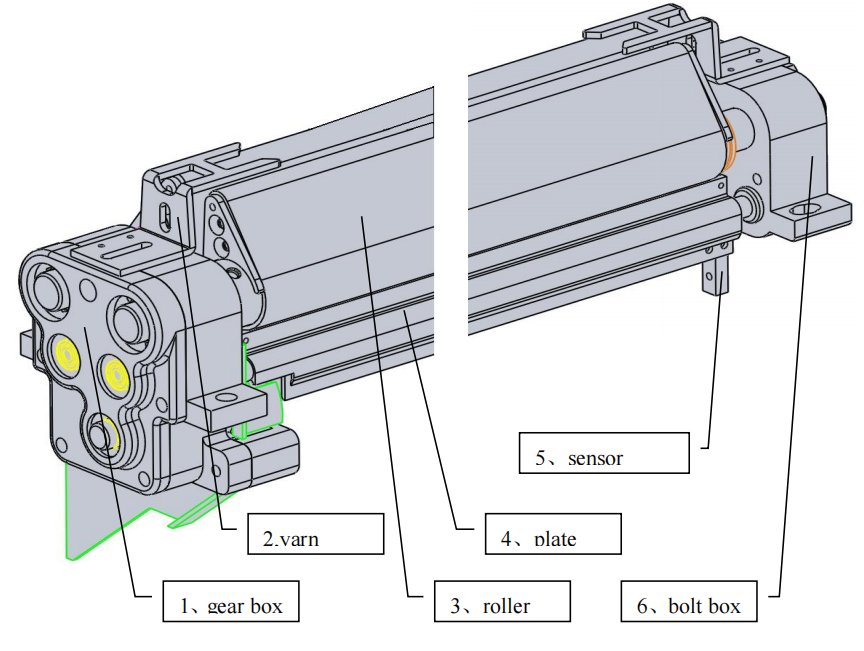

Take down device:

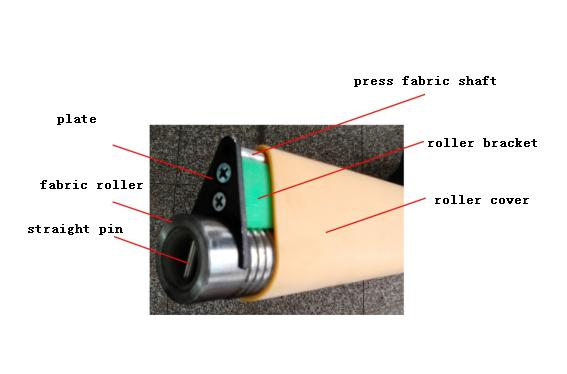

Structure of roller:

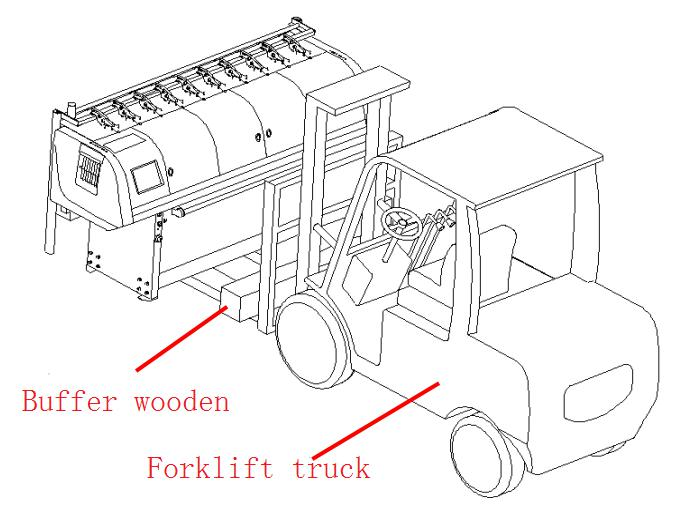

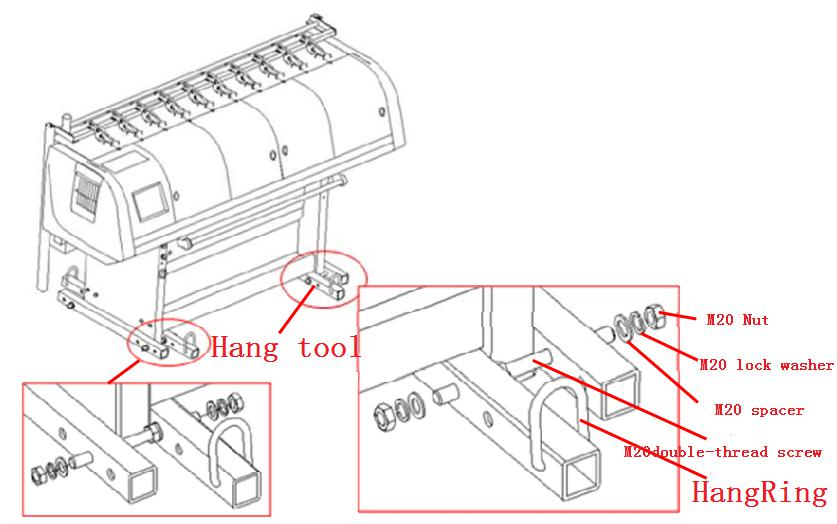

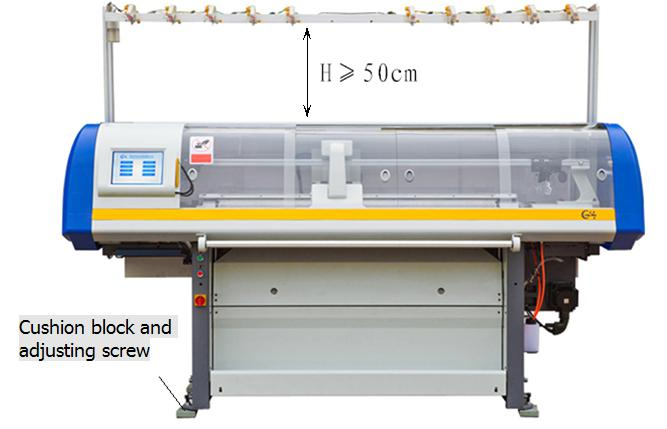

Machine carry and lifting

Installation method

Power requirements

Power supply voltage, frequency 50HZ alternating currents of 220V voltage fluctuation, less than 10 ﹪, voltage fluctuation if more than 10 ﹪, must use stabilizer

Using and maintenance note:

1、While using, according to weave organization, set the appropriate placement of speed, pull speed cannot too fast, lest cause lead force is not stable, and accelerate skin surface wear.

2、When add lubricant for needle bed,don’t make any lubricant grease from needle bed mouth to leak into the skin surface.

3、When using ,please check smeary clean face, and often maintain holster surface dry, clean, prevent pollution pattern or make skin surface increases viscous produce tangled yarn.

4、At any time, remove tangled yarn clearing thrum.

5、Replacement holster methods:

① First, make prevent rewind board, to insert axial direction to push, make body positioning pin from gear case, except under prevent rewind board.

② Loosen inserted axle gear mass screws, will block block pull up remove plug shaft, remove PiGun combination.

③ Replace be over, in the reverse order leather pack to return.

龙星电脑横机常见问题及解决方案

Longxing machine common problems and solutions

为更好的使用电脑横机,产生最佳效益,机器操作人员务必具备一定的针织常识和操作基础知识。在此对一些问题提出原因分析和解决方法,供技术人员在实际问题解决中作为思路参考和技术指导。原因分析和问题解决方法不仅限于以下所列,不可拘泥于此。For better to use computerized knitting machine, to making more effective, machine operator must know the basic knowledge of knitting, and operating experience. To some problem, here give the reasons, and solutions, for technician to solve or a way to find the reason in repairing the machine. The reason and solutions are not limit to the list given.

目录Catalogue

5.度目零位错误及多走少走步数Density zero position error

6.撞针,撞针脚Needle strike, selection jack strike

8.纱嘴不带或不放Yarn feeder no take or always hold

9.上罗拉不转或卡顿upper roller no running or stuck

11.探针非常规报警Probe abnormal alarm

12.卷布假报警或不报警Rewingding error alarm / no alarm

14.CAN2应答异常,通讯错误responds abnormal, community error

17.信克异响或错误Sinker abnormal voice or error

18.其他 Others

1. 编织漏针Knitting loop lose

1.1 检查针是否有损坏 基础常识

Check the needle broken or not basic

1.2 检查纱线是否合适[粗细,强度] 基础常识

Check the yarn is suite or not [ yarn count, strength] basic

1.3 调整纱嘴(宽度,高度) 机头

Adjust yarn feeder [ width, height position] carriage

1.4 调整或换毛刷 机头

Adjust or change brush carriage

1.5 把压针三角调低点或更换压针三角 机头

Put down the pushing needle cam, or change needle pushing cam carriage

1.6 检查翻针三角,编织出高针 机头

Check transfer cam, knitting at the transfer position carriage

1.7 不起针,选针器线松 机头

Needle no selection, selector cable loose carriage

1.8 不起针,清针三角卡住 机头

Needle no selection, needle clearing cam stuck, carriage

1.9 归位块位置 机头

Select needle reset cam position carriage

1.10 抬针三角卡住 机头

select up cam stuck carriage

1.11 齿片,沉降片有瑕疵更换 针板

clip or sinker broken, change it needle bed

1.12 调编织参数(度目,拉力,速度) 参数调整

Adjust knitting parameter [density, takedown tension, speed] parameter adjust

1.13 升级系统 电控

system update electronic control

2. 烂边Fabric side broken

2.1 纱线强度不够 基础常识

yarn strength is weak, change the yarn basic

2.2 调整纱嘴高低,宽窄 机头

Adjust yarn feeder width, up-down position carriage

2.3 调纱嘴停放点 送纱机构

adjust yarn feeder parking position yarn device

2.4 侧张力要合适 送纱机构

side tension value should be suitable yarn device

2.5 画图加偷吃 制版

pattern design uses the miss knit pattern programming

2.6 是否有坏针 针板

check the broken needle needle bed

3. 翻针漏针Transfer loop lose

3.1 机头测试是否有三角,电磁铁不活动 [翻针,接针抬针,换向] 机头

check the cam plate, is any cam or electromagnet not work [transfer, get, needle push, return cam carriage

3.2 检查针是否有损坏[含扩圈片] 针板

check broken needle [ including the transfer clip] needle bed

3.3 调编织参数[度目,拉力,速度] 参数调整

Adjust knitting parameter [density, takedown tension, speed] parameter adjust

3.4 改版,修改收针方式 制版

modify pattern design, the narrowing model pattern programming

3.5 检查调整或更換毛刷 针板

check and change the broken brush needle bed

3.6 调整或更换选针器 机头

check and change the broken selector carriage

3.7 检查总针位(先复位),调整摇床翻针位 机头

check the needle bed zero position [reset first], adjust the transfer needle position carriage

3.8 调整山板接针位置要好 机头

Adjust cam plate, get loop position should be suitable, carriage

4. 度目花Density inconsistent

4.1 检查左右送纱张力 [侧天线,送纱器,储纱器] 机头

check the left and right side tension [side tension device, yarn supply, yarn storage device carriage

4.2 更换度目轴承 参数调整

change density bearing parameter adjust

4.3 度目补正 机头

density correction carriage

4.4 更换度目马达 机头

change density motor carriage

4.5 度目三角卡住清理或更换 机头

density cam stuck, clean or change carriage

4.6 更换度目夹子 机头

change the density clamp carriage

4.7 检查信克是否卡住,并清理。信克参数[开关,大小] 机头

check the sinker is stuck or not, and clean it. Sinker parameter [switch, value] carriage

5. 度目零位错误及多走少走步数Density zero position error

5.1 零位线松动重新接 机头

zero position cable loose,check connection carriage

5.2 换度目感应器 机头

change density sensor carriage

5.3 更换度目夹子 机头

change density clamp carriage

5.4 检查度目三角是否卡死清理 机头

check the density cam stuck or not, clean it, carriage

5.5 更换度目马达 机头

change density motor carriage

5.6 调低度目工作和保持电流 参数调整

turn down density working and holding current parameter adjust

6. 撞针,撞针脚Needle strike, selection jack strike

6.1 纱线,度目,拉力是否合适 牵拉机构

check the yarn, density, and tension suitable or not take down device

6.2 调整纱嘴宽窄高低 送纱机构

adjust yarn feeder width and up-down position yarn device

6.3 测试机头是否有不活动的三角电磁铁[度目,吊目,接针,起针,中山导块] 机头

Carriage checking, if any cam or electromagnet is stuck [density, tuck, get loop, needle push, transfer], carriage

6.4 三角有毛刺或损坏,打磨或更换 机头

carriage not smoothly or broken, polish or change carriage

6.5 清理机头,针板异物,上油 机头

clean cam plate, clean needle bed carriage

6.6 检查更换选针器 机头

check and change needle selector carriage

6.7 归位块间隙不合适调整 机头

reset cam space to cam plate,adjusting carriage

6.8 检查修改花样 制版

check and modify pattern design programming

6.9 机头与针板间隙 机头

The space of carriage and needle bed Carriage

6.10 机头轴承松动,调合适

The carriage bearing loose, need adjust

7. 乱选针Select wrong needle

7.1 选针器刀片是否有损坏,角度调整,更换选针器 机头

Check the head of selector, adjust the angle, change the selector Carriage

7.2 选针脚更换 机头

Change the select Jack needle Carriage

7.3 校对针零位 参数调整

Adjust the zero position of needle bed Adjust the parameter

7.4 弹簧针或不织压片磨损,更换

Change the spring Jack needle or no knit cam

7.5 选针归位块间隙及有异物

Check the space of select reset cam, or clean it

7.6 山板与针板间隙

The space of cam plate and needle bed

7.7 机头线接触不良或故障 机头

Bad contact or malfunction of carriage wire Carriage

7.8 机头与同步带连接松动 机头

Loose connection between carriage and synchronous belt Carriage

8. 纱嘴不带或不放Carriage no take feeder or no release feeder

8.1 更换换色电磁铁 机头

Change the feeder electromagnet Carriage

8.2 换色顶杆弹簧松紧要合适 机头

Adjust the spring of feeder electromagnet Carriage

8.3 调整电磁铁释放电流 参数调整

Adjusting the Release Current of Electromagnet, adjust parameter

8.4 纱嘴松紧要合适,天杠适当加油 送纱机构

Suitable for tightening of feeder, give oil in feeder

9. 上罗拉不转或卡顿Main roller No Turn or Carton

9.1 调紧链条 牵拉机构

Adjust the chain more tighter Take down device

9.2 更换罗拉电机 牵拉机构

Change roller motor Take down device

9.3 齿轮箱卡住,清理 牵拉机构

Roller gear box stuck, clean it Take down device

9.4 更换罗拉驱动器 电控 损坏情况:见超哥文档

Change Roller driver Electronic control

9.5 扩展板更换 电控

Change expansion board Electronic control

9.6 温度过低或新罗拉运转不顺,先慢速预热 牵拉机构

Temperature too low or new roller too tight, slow run first Take down device

10. 机头不动Carriage no move

10.1 检查主伺服[查询相应报警代码],主马达 《断电拔掉主马达插头》

Check main servo <the code of alarm Main motor

10.2 皮带损坏 机头

Belt broken Carriage

10.3 参数错误,读入原始参数 参数调整

Parameter wrong, read original parameters Adjust parameter

10.4 增加机器参数的总脉冲 参数调整 《无需展现》

Increase overall Pulse in Machine Parameters Adjust parameter

11. 探针非常规报警Probe Unconventional alarm

11.1 纱嘴停放点要错开位置 参数调整

Feeder packing position need staggered Adjust parameter

11.2 探针位置调整 机头

Adjust the probe position Carriage

11.3 更换探针 机头

Change probe Carriage

12. 上下罗拉报警或不报警Fabric rewind alarm

12.1 感应器位置调整 牵拉机构

Adjust the sensor position Take down device

12.2 感应器损坏 牵拉机构

Change sensor Take down device

12.3 频繁报警,罗拉皮磨损严重 牵拉机构

Alarm many times, roller use too long time, change rubber roller. Take down device

12.4 布片卷入罗拉中

12.5 下罗拉落布锤报警,及倒卷板报警

13. 起底板异常Comb abnormal

13.1 位置过高,字码调松 参数调整

Position too high, density change loose Adjust parameter

13.2 位置过高,安全位调整 参数调整

Position too high, adjust safety position Adjust parameter

13.3 起底板不勾纱,微动开关损坏或位置 电控

Comb no hook the yarn, The micro switch damage or wrong position Electronic control

13.4 起底板一直上升不下降,更换零位微动开关,更换信号采集板,更换刹车模块电控,起底板马达感应盘磁铁。

Comb up and no stop, change micro switch of zero position, change signal Acquisition Board, change brake module Electronic control

13.5 起底板不动,力矩控制器坏

Comb no move, comb driver damage.

14. CAN2应答异常,通讯错误CAN2 abnormal, Communication error

14.1 机头线检查 电控 《系统测试自检》

Check carriage Circuit Electronic control

14.2 伺服接线检查 电控 《检查线路是否松动,扩展板及罗拉驱动器》

Check server wiring Electronic control

14.3 扩展板主板线路检查 电控

Inspection of Extended Board and Main Board Circuit Electronic control

15. 伺服器报警Servo Alarm

15.1 查看显示代码,查询相应处理 电控

Check the code of servo display, see the list of corresponding treatment Electronic control

15.2 更换大排线 电控

Change main wire Electronic control

15.3 更换主电机 电控

Change main motor Electronic control

15.4 伺服无显示,更换伺服器 电控

Servo no light, change the servo Electronic control

16. 黑屏Black screen

16.1 是否通电 电控

Whether to electrify or not Electronic control

16.2 更换显示器 电控

Change display Electronic control

16.3 更换主控箱 电控

Change the main board Electronic control

17. 信克异响或错误Sinker abnormal sound or wrong

17.1 信克参数[参数大小,开关]

Sinker parameter <Parameter change>

17.2 调整信克马达与齿条间的距离 机头

Adjust the distance between Sinker Motor and rack Carriage

17.3 更换信克马达 机头

Change sinker motor Carriage

18. 其他Other

18.1 蜂鸣器不响 更换蜂鸣器! 电控

The buzzer is silent. Replace the buzzer Electronic control

18.2 送纱器没力 更换电容 电控

Yarn supplier running slow, change the capacitance Electronic control

18.3 储纱器不转

Yarn storage device not work

18.4 接触不良 送纱机构

Poor contact Yarn device

18.5 更换储纱器 送纱机构

Change Yarn storage device Yarn device

18.6 更换控制板 电控

Change control Board Electronic control

For more information,please kindly check video and file in following:

QR CODE

QR CODE